10 Micron GM1000 HPS EP

- Stock: 3-4 Months

- Model: 10M1030

Evolving perfection.

The new GM1000 HPS EP (Enhanced Performance) mount is the evolution of the very popular GM1000 HPS; thanks to some important mechanical improvements, the paylod of this new mount is now 30kg / 66 lb. (counterweights not included); the typical optics suitable for this mount are 150 mm diameter refractors, 200 mm diameter Newton reflectors, 280 mm diameter Cassegrains and similar. Movements are driven by two servo brushless motors, with timing belt reduction having zero backlash. Both axes feature a classic worm – wormwheel pairing. The wormwheels are made of bronze (B14), with a diameter of 125mm and 250 teeth, while the worms are built of alloy steel with a diameter of 20mm. The axes themselves are made of 32mm (Ra) and 30mm (DEC) diameter alloy steel, for the maximum rigidity. The double dovetail mounting plate guarantees the maximum compatibility with many telescope manufacturers.

The GM1000 HPS EP is the culmination of a dedicated R&D process to enhance the mount’s core structure and technology. Futhermore, years of field-testing by users worldwide, who often pushed the mount near its limits with excellent results, provided us with invaluable data and the confidence to take the next step. Every improvement delivers a tangible benefit to the astrophotographer.

- Increased Payload Capacity to 30 kg (66 lb.): Allows for the use of heavier and more complex optical setups—such as larger telescopes and heavy camera systems—while preserving maximum stability.

- Reinforced axes: Both RA and DEC axes have been improved with a new design and an increased thickness. RA axis diameter has also been increased in diameter.

The result is an exponential increase in structural rigidity that dramatically reduces flexure and vibrations. - New, Larger Bearings: Corresponding with the new axis, larger and reinforced bearings provide smoother movements and superior management of the increased load, ensuring the longevity of the mechanics.

- Redesigned Housings and Worm Gear Supports: The mechanical housings have been optimized to integrate more robust worm gear supports, minimizing flexure in the drive system to ensure flawless tracking.

- Enhanced Manufacturing Precision: The use of new CNC machinery and 3D coordinate measuring machines (CMM) allows for tighter mechanical tolerances and guarantees consistent quality across every unit.

- New V3 Control Box: Modernized electronics and industrial-grade, EU-made connectors deliver superior performance, faster command response, and robust, long-lasting connections.

- Selective Sourcing of Materials: A rigorous selection process for all metal alloys and electronic components ensures top-tier performance and reliability in every detail.

- Enhanced Connectivity and Web Interface: Advanced connectivity options, including a sophisticated web interface, provide reliable remote usability and allow for comprehensive monitoring and control without physical interaction.

- Optimized for Remote Operation: The mount’s inherent reliability and robust design, combined with its advanced connectivity, enable seamless and dependable remote operation. It is backed by a worldwide sales and technical support network.

The electronics is housed in an independent control box (new version V3), easily removable. The connections of motors, encoders and hand pad feature security lock screws. The mount can be controlled using the included hand pad, without connecting an external PC. The keypad is built in order to maintain the maximum readability in all lighting conditions. Both the display and the ergonomic keys, allowing for the use of gloves, feature a red backlight. An heater keeps the display warm for usage below freezing temperatures.

Main features of the new Controlbox V3:

• Advanced Mainboard: New ARM based processor for enhanced performance and future-proofing.

• High-Quality Industrial Connectors: All power and data connections feature high-quality Binder connectors from Germany, ensuring superior protection against moisture, dust, and environmental hazards.

• Enhanced Connectivity: A dedicated port for an external WiFi antenna improves wireless communication capabilities.

• Optimized Data Interfaces: New RJ ports for LAN, Autoguide, and GPS ensure reliable signal transmission.

• Precision GPS Integration: The GPS module connects via a PS2 interface (instead of RJ), featuring a built-in PPS signal for ultra-precise timekeeping, ideal for satellite tracking applications.

• Professional Power Connector: The previous connector is replaced with a two-pin Binder plug for 24V DC power. A new power cable is included.

• Expanded AUX Interface: A 6-pin AUX port (DIN EN 61076-2-106) enhances remote switch control and power-on feedback

The mount can be controlled using the most common software packages by connecting it to a PC with the RS-232 serial port or the Ethernet connection, via the proprietary 10Micron ASCOM driver or the Meade compatible command protocol. Furthermore, a dedicated software (also included with the mount) can be used to create a “virtual hand pad” replicating exactly the functions of the physical hand pad. The RS-232 port can also be used to control an external dome. This flexibility makes the GM1000HPS EP an ideal mount for observatories and remotized observing sites. The object database contains many star catalogs and deep-sky objects up to the 16th magnitude. Solar system objects can be tracked so that their motion is compensated with respect to the stars. You may load orbital elements of comets, asteroids and artificial satellites into the mount, so that these objects can be tracked directly using the hand pad (without any external PC).

Pointing is made accurate through the usage of a model containing up to 100 stars, which allows for the correction of the classical polar alignment and conic errors, and also of the most important flexure terms of the optical tube. In this way it is possible to obtain pointing accuracies of the order of 20 arcseconds RMS. The same model can be used in order to obtain the maximum tracking accuracy, compensating also for the atmospheric refraction (depending on the local atmospheric pressure and temperature). A series of auxiliary functions is provided to help the user for quick aligning the mount to the celestial pole. You may save and recover the alignment data of different observing sessions. This function is very useful if you have many instruments in different setups, each one requiring different flexure corrections.

Tracking through the meridian, a typical problem with german mounts, is solved allowing for tracking for up to 30° past the meridian (configurable), in both directions. In this way any object can be tracked for at least four hours.

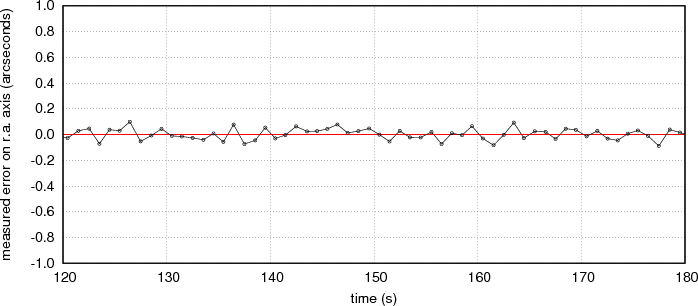

The tracking accuracy makes autoguiding not necessary for many uses. The absolute encoders on both axes allows to obtain a typical tracking error below 1 arcsecond.

It is possible to autoguide anyway, using the ST4-compatible port or through the serial/Ethernet connection, with a guide rate configurable from 0.1x to 1x. The guide rate can be automatically corrected for the declination of the target, so that there is no need of recalibrating the autoguide when observing at different declinations.

Designed for field use, the GM1000HPS EP is easily transportable. The main body of the mount, without the counterweight shaft, has a weight of only 19.5 kg – 43 lbs.

Other functions of the mount are designed in order to obtain the maximum flexibility in the most usage conditions.

The mount can be switched on and off using the dedicated connector on the control box panel. You can use the electronic balance functions in order to balance your instrument without unlocking the clutches.

The mount can be parked in different user-defined positions. An external dome can be controlled directly using the RS-232 serial port, avoiding the need of using a dedicated external PC. Once configured with your instrument parameters, the firmware is able to make all the calculations required for positioning the dome slit in front of your optical tube, for almost all instrument configurations.

NEW Web interface!

The new control interface is accessible through any web browser – no additional software or PC required. The mount is displayed on the local network directly under its device name. Features of the new interface (from firmware 3.0onwards):

• Direct access to the user manuals and command protocols

• Download of TLE data as well as comet and asteroid data

• Automatic firmware check and easy updates

• Virtual hand controller with all the functions of the physical keypad

• Compatible with any browser and any device (PCs, laptops, tablets, and smartphones) as well as all operating systems

Important: Full functionality of the new web interface is only available with firmware version 3.0 or higher.

GM 1000 HPS EP Equatorial Mount Head (Standard Package), including:

GM 1000 HPS EP Mount with precision absolute axis-encoders, motor control box with onboard-intelligence (Linux-processor), V. 3 – HPS version firmware, stand alone system (no PC required), professional handcontrol unit with graphic display and temperature control, cables, counterweight bar, pier adapter for tripod / column, strong transport carton-box with shaped foam, WiFi option included

GM 1000 HPS EP Equatorial Mount Head (Standard Package), including:

- GM 1000 HPS EP Mount with built-in precision absolute axis-encoders

- Control box with onboard-intelligence (Linux-processor), stand alone system ( no PC required , V. 2 – HPS version firmware

- Professional handcontrol unit with graphic display and temperature control – 10M5030

- Cables

- Counterweight bar, standard lenght, for paylaods up to 25 kg (an optional XL bar can be purchased for payloads from 25 kg to 30 kg, – 10M1039XL)

- Pier adapter for tripod / column – 10M1090

- Strong transport carton-box with shaped foam – 10M1066

- Allen key set

- WiFi option included

| Type | German Equatorial Mount |

| Weight (mount) | 19.5 kg – 43 lb. without accessories |

| Instrument payload capacity | ~ 30 kg – 66 lb. |

| Latitude range | 0° – 82° (90° optional) |

| Azimuth fine adjustment range | +/− 7.5° |

| Counterweight shaft | 30 mm diameter, stainless steel, weight 1.7 kg – 3.7 lb. For payloads between 25 kg (55 lb.) and 30 kg (66 lb.) the optional XL bar (10M1039XL) is necessary |

| Axes | RA 32 mm / DEC 30 mm diameter, alloy steel |

| Bearings | Pre-loaded tapered roller bearings Roller thrust bearings |

| Worm wheels | 250 teeth, 125 mm diameter, B14 bronze |

| Worms | diameter 20mm, alloy steel, grinded and lapped |

| Transmission system | Backlash-free system with timing belt and automatic backlash recovery |

| Motors | 2 axes servo brushless |

| Power supply | 24 V DC |

| Power consumption | ~ 0,5 A while tracking ~ 3 A at maximum speed ~ 4 A peak |

| Go-to speed | Adjustable from 2°/s to 15°/s |

| Pointing accuracy | < 20” with internal multiple-stars software mapping |

| Average tracking accuracy | < +/− 1" typical for 15 minutes (< 0.7" RMS) with multiple-stars software mapping and compensation of flexure and polar alignment errors |

| Security stop | +/− 30° past meridian in r.a. (software) +/− 45° past meridian in r.a. (mechanical) |

| Operational temperature range (standard) | - 15° C to + 35° C + 05° F to + 95° F |

| Communication ports | RS–232 port; GPS port; autoguide ST-4 protocol port; Ethernet port |

| Database | Stars: by name, Bayer designation, Flamsteed designation, Bright Star Catalogue, SAO, HIP, HD, PPM, ADS, GCVS. Deep-sky: M, NGC, IC, PGC ,UGC limited up to mV = 16. Solar system: Sun, Moon, planets, asteroids, comets, artificial satellites. Equatorial and altazimuth coordinates. User defined objects, fast slewing positions. |

| Firmware features | User defined mount parking position, 2‑stars and 3‑stars alignment function, up to 100 alignment stars for modeling, correction of polar alignment and orthogonality errors, estimate of average pointing error, storage of multiple pointing models, sidereal, solar and lunar tracking speed adjustable on both axes, declination-based autoguide speed correction, adjustable horizon height limit, pointing and tracking past meridian,, assisted balance adjustment, manual or GPS based time and coordinates setting, dome control via RS-232, configurable atmospheric refraction, network settings, comets and asteroids filter, multi-language interface. Remote Assist via Internet connection. |

| PC control | Remote control via RS-232 or Ethernet; proprietary ASCOM driver or Meade compatible protocol; update of firmware and orbital elements of comets, asteroids and artificial satellites via RS-232 or Ethernet; virtual control panel via RS-232 or Ethernet. Wi-Fi included to control the mount via Tablet, Smartphone etc. Web interface |

| Web interface | • Direct access to the user manuals and command protocols • Download of TLE data as well as comet and asteroid data • Automatic firmware check and easy updates • Virtual hand controller with all the functions of the physical keypad • Compatible with any browser and any device (PCs, laptops, tablets, and smartphones) as well as all operating systems |

GM 1000 HPS EP Equatorial Mount Head (Standard Package), including:

- GM 1000 HPS EP Mount with built-in precision absolute axis-encoders

- Control box with onboard-intelligence (Linux-processor), stand alone system ( no PC required , V. 2 – HPS version firmware

- Professional handcontrol unit with graphic display and temperature control – 10M5030

- Cables

- Counterweight bar, standard lenght, for paylaods up to 25 kg (an optional XL bar can be purchased for payloads from 25 kg to 30 kg, – 10M1039XL)

- Pier adapter for tripod / column – 10M1090

- Strong transport carton-box with shaped foam – 10M1066

- Allen key set

- WiFi option included